1390 Umatshini wokusika ochanekileyo

Umboniso weMveliso

Ipharamitha yobugcisa

| Indawo yokusebenza | 1300*900mm | Laser Head Brand | Raytools |

| Ifayibha laser amandla | Ngokuzikhethela: 1000W/1500w/2000w/3000W njl. | Amacandelo Angundoqo | Imoto |

| Isantya esiphezulu sokusika | 0-40m/min | Uphawu:

| Ifakwe ngokupheleleyo |

| Phinda ukuchaneka kwendawo | 0.02mm | Indlela yokuSebenza | iliza eliqhubekayo |

| ukunikezwa Amandla | 220v/50Hz/60Hz | imoto kunye nomqhubi | IJapan YASKAWA i-servo motor & nomqhubi / isinciphisi sesiFrentshi |

| Ubushushu bendalo | 0-35°C | IFomathi yoMzobo iyaxhaswa | I-AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Ixesha eliqhubekayo lokusebenza | iiyure ezingama-24 | Indawo yokusika | 1300*900mm,1300*1300mm |

| Ubunzima bomatshini | 1500kg | Amanqaku okuThengisa aPhambili | Ukuchaneka okuphezulu |

| Ubomi bendalo be-laser | Iiyure ezingama-100000 | Inkqubo yothumelo | Ukudluliselwa kwebhola Screw |

| Isoftware yokulawula | Cypcut | MAX ukukhawuleza | 0.5G |

| Inkqubo yokupholisa | Ukupholisa amanzi | Phinda ukuchaneka kwendawo:

| ±0.006mm |

Ukusika ubukhulu

| Ipharamitha yokusika iLaser | ||||||||

|

| 500W | 1000W | 2000W | 3000W | 4000W | 6000W | 8000W | |

| Izinto eziphathekayo | Ukutyeba | isantya m/min | isantya m/min | isantya m/min | isantya m/min | isantya m/min | isantya m/min | isantya m/min |

| Intsimbi yekhabhoni | 1 | 8--13 | 15--24 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 3.0--4.5 | 5--7.5 | 5.5--8 | 7--9 | 8--10 | 9--12 | 10--13 | |

| 3 | 1.8--3.0 | 2.4--4 | 3.5-4.8 | 4--6.5 | 4.5--6.5 | 4--7 | 4--7 | |

| 4 | 1.3-1.5 | 2--2.4 | 2.8-3.5 | 3.5--4.5 | 4.0--5.0 | 4.2--5.5 | 4.7--5.5 | |

| 5 | 0.9--1.1 | 1.8--2 | 2.5--3 | 3--3.5 | 3.0--4.2 | 3.5--4.2 | 3.8--4.5 | |

| 6 | 0.6--0.9 | 1.4--1.6 | 1.8--2.6 | 2.5--3.2 | 3.0--3.5 | 3.0--4 | 3.3--4.2 | |

| 8 |

| 0.8--1.2 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | 2.2--3.2 | 2.5--3.5 | |

| 10 |

| 0.6--1.0 | 1.1-1.3 | 1.4--2.0 | 1.5--2.5 | 1.8--2.5 | 2.2--2.7 | |

| 12 |

| 0.5--0.8 | 0.9--1.2 | 1.2--1.6 | 1.4--2 | 1.6--2 | 1.8--2.1 | |

| 14 |

|

| 0.7-0.8 | 0.9--1.4 | 1.0--1.6 | 1.5--1.8 | 1.7--1.9 | |

| 16 |

|

| 0.6-0.7 | 0.8--1.2 | 0.8--1.2 | 0.8--1.5 | 0.9--1.7 | |

| 18 |

|

| 0.4--0.6 | 0.7--1 | 0.8--1.1 | 0.9--1.2 | 0.9--1.2 | |

| 20 |

|

|

| 0.6--0.8 | 0.7--1 | 0.8--1.1 | 1.0--1.5 | |

| 22 |

|

|

| 0.4--0.6 | 0.6--0.8 | 0.7--0.9 | 0.8--1.0 | |

| 25 |

|

|

|

| 0.3--0.5 | 0.4--0.6 | 0.5--0.7 | |

| Yenziwe ngentsimbi eshayinayo | 1 | 8--13 | 18--25 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 2.4--5.0 | 7--12 | 10--17 | 18--21 | 20--30 | 30--42 | 40--55 | |

| 3 | 0.6--0.8 | 1.8--2.5 | 4--6.5 | 8--12 | 12--18 | 18--24 | 30--38 | |

| 4 |

| 1.2--1.3 | 3--4.5 | 6--9 | 8--12 | 10--18 | 18--24 | |

| 5 |

| 0.6--0.7 | 1.8-2.5 | 3.0--5.0 | 4--6.5 | 8--12 | 12--17 | |

| 6 |

|

| 1.2-2.0 | 3.0--4.3 | 4.0--6.5 | 6--9 | 8--14 | |

| 8 |

|

| 0.7-1 | 1.5--2.0 | 1.8--3.0 | 4--5 | 6--8 | |

| 10 |

|

|

| 0.8--1 | 0.8--1.5 | 1.8--2.5 | 3--5 | |

| 12 |

|

|

| 0.5--0.8 | 0.6--1.0 | 1.2--1.8 | 1.8--3 | |

| 15 |

|

|

|

| 0.5--0.8 | 0.6--0.8 | 1.2--1.8 | |

| 20 |

|

|

|

| 0.4--0.5 | 0.5--0.8 | 0.6--0.7 | |

| 25 |

|

|

|

|

| 0.4--0.5 | 0.5--0.6 | |

| 30 |

|

|

|

|

|

| 0.4--0.5 | |

| Aluminiyam | 1 | 4--5.5 | 6--10 | 20--25 | 25--40 | 40--55 | 55--65 | 80--90 |

| 2 | 0.7--1.5 | 2.8--3.6 | 7--10 | 10--18 | 15--25 | 25--35 | 35--50 | |

| 3 |

| 0.7--1.5 | 4--6 | 7--10 | 10--15 | 13--18 | 21--30 | |

| 4 |

|

| 2--3 | 4--5.5 | 8--10 | 10--12 | 13--18 | |

| 5 |

|

| 1.2-1.8 | 3--4 | 5--7 | 6--10 | 9--12 | |

| 6 |

|

| 0.7--1 | 1.5--2.5 | 3.5--4 | 4--6 | 4.5--8 | |

| 8 |

|

|

| 0.7--1 | 1.5--2 | 2--3 | 4--6 | |

| 10 |

|

|

| 0.5--0.7 | 1--1.5 | 1.5--2.1 | 2.2--3 | |

| 12 |

|

|

|

| 0.7--0.9 | 0.8--1.4 | 1.5--2 | |

| 15 |

|

|

|

| 0.5--0.7 | 0.7--1 | 1--1.6 | |

| 20 |

|

|

|

|

| 0.5--0.7 | 0.7--1 | |

| 25 |

|

|

|

|

|

| 0.5--0.7 | |

| Ubhedu | 1 | 4--5.5 | 6--10 | 14--16 | 25--35 | 35--45 | 50--60 | 70--85 |

| 2 | 0.5--1.0 | 2.8--3.6 | 4.5--6.5 | 10--15 | 10--15 | 25--30 | 30--40 | |

| 3 |

| 0.5--1.0 | 2.5--3.5 | 5--8 | 7--10 | 12--18 | 15--24 | |

| 4 |

|

| 1.5--2 | 3.5-5.0 | 5--8 | 8--10 | 9--15 | |

| 5 |

|

| 1.4-1.6 | 2.5--3.2 | 3.5-5.0 | 6--7 | 7--9 | |

| 6 |

|

|

| 1.2--2.0 | 1.5--2.5 | 3.5--4.5 | 4.5--6.5 | |

| 8 |

|

|

| 0.7-0.9 | 0.8--1.5 | 1.6--2.2 | 2.4--4 | |

| 10 |

|

|

|

| 0.5--0.8 | 0.8--1.4 | 1.5--2.2 | |

| 12 |

|

|

|

|

| 0.6--0.8 | 0.8--1.5 | |

| 16 |

|

|

|

|

|

| 0.6--0.8 | |

Amacandelo Angundoqo

Isicelo

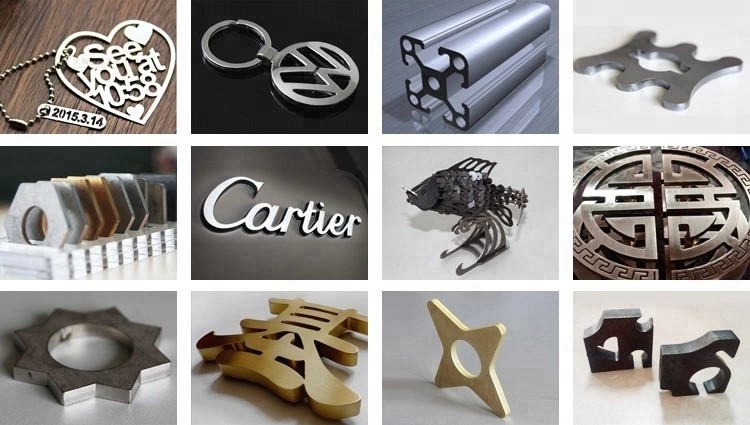

Ishishini lesicelo:

I-1390 i-High Precision laser Cutting Machine isetyenziswa ngokubanzi kwi-Billboard, iNtengiso, iMiqondiso, iMiqondiso, iileta zeMetal, iiLetter ze-LED, i-Kitchen Ware, iileta zentengiso, i-Sheet Metal Processing, i-Metals Components kunye naMacandelo, i-Ironware, i-Chassis, i-Racks & Cabinets Processing, i-Metal Crafts, i-Metal Crafts, i-Hardware Art Ware. Isakhelo, iiNdawo ze-Electronic, ii-Nameplates, njl.njl.ukuqinisekisa ukuba inokusebenza ngokunokwenzeka ngexesha lenkqubo yokusika i-laser.

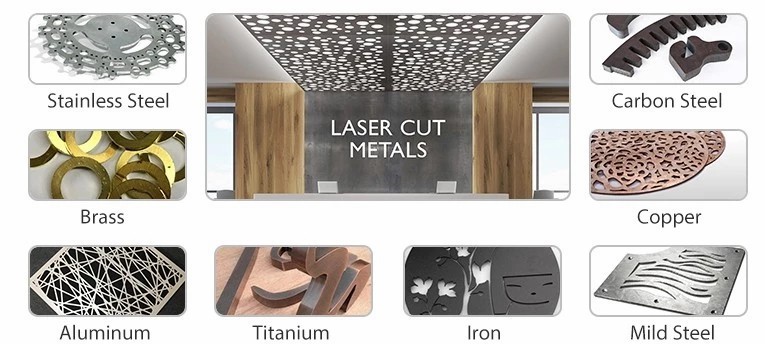

Izixhobo zokusebenza:

I-Stainless Steel Sheet, i-Mild Steel Plate, i-Carbon Steel Sheet, i-alloy Steel Sheet, i-Spring Steel Sheet, i-Iron Plate, i-Iron Galvanized, i-Galvanized Sheet, i-Aluminiyamu Plate, i-Copper Sheet, i-Bronze Plate, i-Gold Plate, i-Silver Plate, i-Titanium Plate, i-Metal Sheet, i-Metal Sheet, i-Tube, njl.

Iisampulu

Inzuzo

1.Ukusika kakuhle, ukuya kuthi ga kwi-0.05-0.1mm. Sebenzisa igesi encedisayo efanelekileyo, ukwenza i-slits icoceke kwaye igudileyo, ayifuni ukupholisa okwesibini.

I-2.Ukugxininisa intloko yokusika ngokuzenzekelayo.ukusetyenziswa kwe-sensor ye-capacitive ephezulu evela kumazwe angaphandle, i-full-time-dynamic tracking plate height.Ukulungelelanisa ukuphakama kokusika ngokuzenzekelayo okuthintela ukungqubana, unokunqumla i-plate engalinganiyo.

3. Umatshini wokusika uthatha i-servo motor drive evela kumazwe angaphandle, ukungenisa imodyuli echanekileyo ephezulu, ngokukhawuleza, ukuchaneka okuphezulu ukuya kwi-0.01mm. Ubomi benkonzo ende.

I-4.Ukusetyenziswa kwe-laser fibers eziphambili, izixhobo eziphambili zingeniswa ngaphandle. Uzinzo oluphezulu, ubomi obude, akukho zibonelelo, simahla.

5.Uyilo lobuchwephesha lwesixhobo sokubuyisela umgubo wegolide, uthuli nothuli luqokelele sonke isixhobo sokubuyisela. Ukuze ilahleko ibe ubuncinane.

I-6.Ishishini lezacholo zegolide kunye nesilivere yenkqubo yokusika i-laser yesiko, kunye nokulungiswa kwendlela, ukusika indawo yokuqalisa, i-multi-layer, umsebenzi wokubeka, ukonga ixesha kunye nezinto eziphathekayo.

7.Ubungakanani obuncinci, ukusetyenziswa kwamandla aphantsi, ukubonelela okuncinci, ukugcinwa lula. Ngomoya ocinezelweyo unokunqunyulwa, ixabiso eliphantsi.