Umatshini wokuWelding weLaser ophathwa ngesandla

Icandelo lomxholo wenkcazo emfutshane

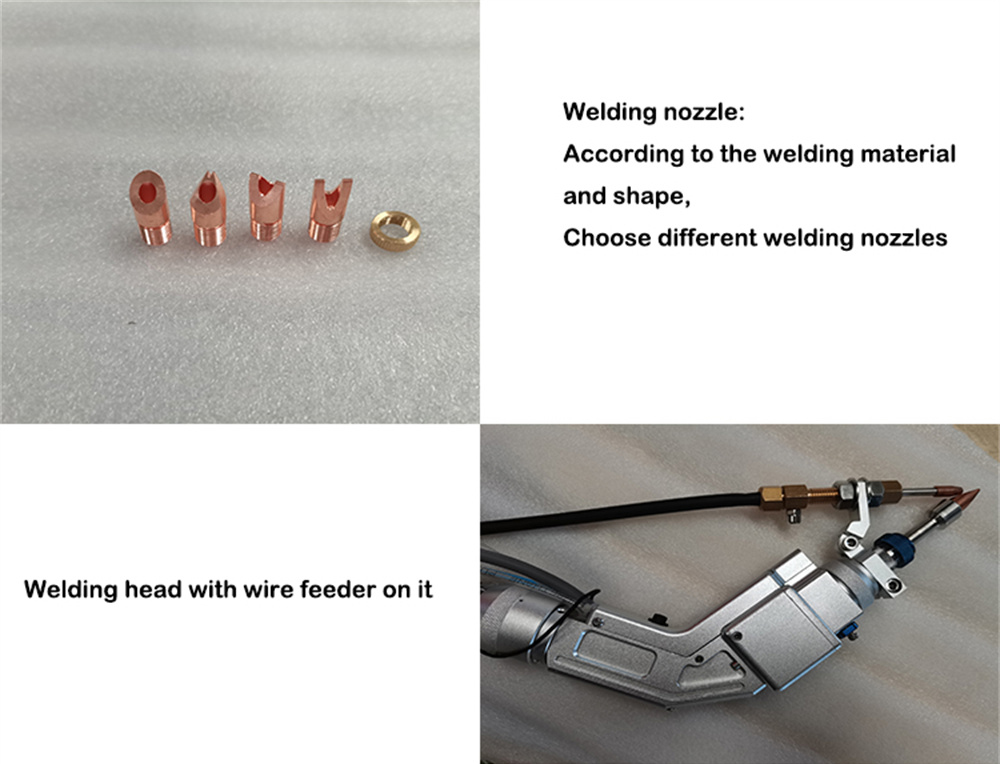

- Kukho iindlela ze-welding ezi-6 kunye nemilomo ye-welding ezininzi ukuhlangabezana neemfuno ze-welding ezahlukeneyo; inomsebenzi wenzwa yokhuseleko, ekhupha i-laser emva kokuchukumisa isinyithi kwaye ivale ngokuzenzekelayo ukukhanya xa isusiwe.

- Umatshini uxhotyiswe ngesixhobo sokutya okuzenzekelayo, esinokuhlengahlengisa ngokulula iiparamitha kunye nokubonelela ngeendlela ezininzi zokukhetha.

abathengi.

- Kukho iindlela ze-welding ezi-6 kunye nemilomo ye-welding ezininzi ukuhlangabezana neemfuno ze-welding ezahlukeneyo; inomsebenzi wenzwa yokhuseleko, ekhupha i-laser emva kokuchukumisa isinyithi kwaye ivale ngokuzenzekelayo ukukhanya xa isusiwe.

- Ubushushu obuphindwe kabini kunye nolawulo olubini, ukujikeleza kwamanzi okujikelezayo, kunokupholisa ngokukhawuleza umbhobho wangaphakathi wentloko ye-welding, ngelixa upholisa i-laser.

Umboniso weMveliso

Ipharamitha yobugcisa

| Imeko | Entsha | Amacandelo Angundoqo | Umthombo weLaser |

| Ukusetyenziswa | Weld Metal | Max. Amandla emveliso | 2000W |

| Izinto Ezinokusetyenziswa | Isinyithi | Cnc Okanye Hayi | Ewe |

| Imo yokupholisa | Ukupholisa Amanzi | Isoftware yokulawula | URuida/Qilin |

| Pulse Ububanzi | 50-30000Hz | Amandla eLaser | 1000w/1500w/2000w |

| Ubunzima (Kg) | 300 Kg | Isiqinisekiso | Ce, Iso9001 |

| Amacandelo Angundoqo | IFayibha Laser Umthombo, iFayibha, Handle Laser Welding Head | Amanqaku okuThengisa aPhambili | Ukuchaneka okuphezulu |

| Umsebenzi | Metal Part Laser Welding | Ubude beFayibha | ≥10m |

| Amashishini asebenzayo | Iihotele, iiVenkile zeMpahla, iiVenkile zezinto zokwakha | Amacandelo Angundoqo | Ubonelelo ngeLaser |

| Indlela yokuSebenza | Nditsalekile | Emva kweNkonzo yeWaranti | Inkxaso ye-Intanethi |

| Ububanzi beNdawo ekuJoliswe kuyo | 50μm | Ubude bamaza | 1080 ±3nm |

| Uhlolo lwevidiyo oluphumayo | Kubonelelwe | IFomathi yoMzobo iyaxhaswa | Ai, Plt, Dxf, Dwg, Dxp |

| Indawo Yemvelaphi | IJinan, kwiPhondo laseShandong | Ixesha leWaranti | Iminyaka emi-3 |

Izahlulo eziphambili zoomatshini

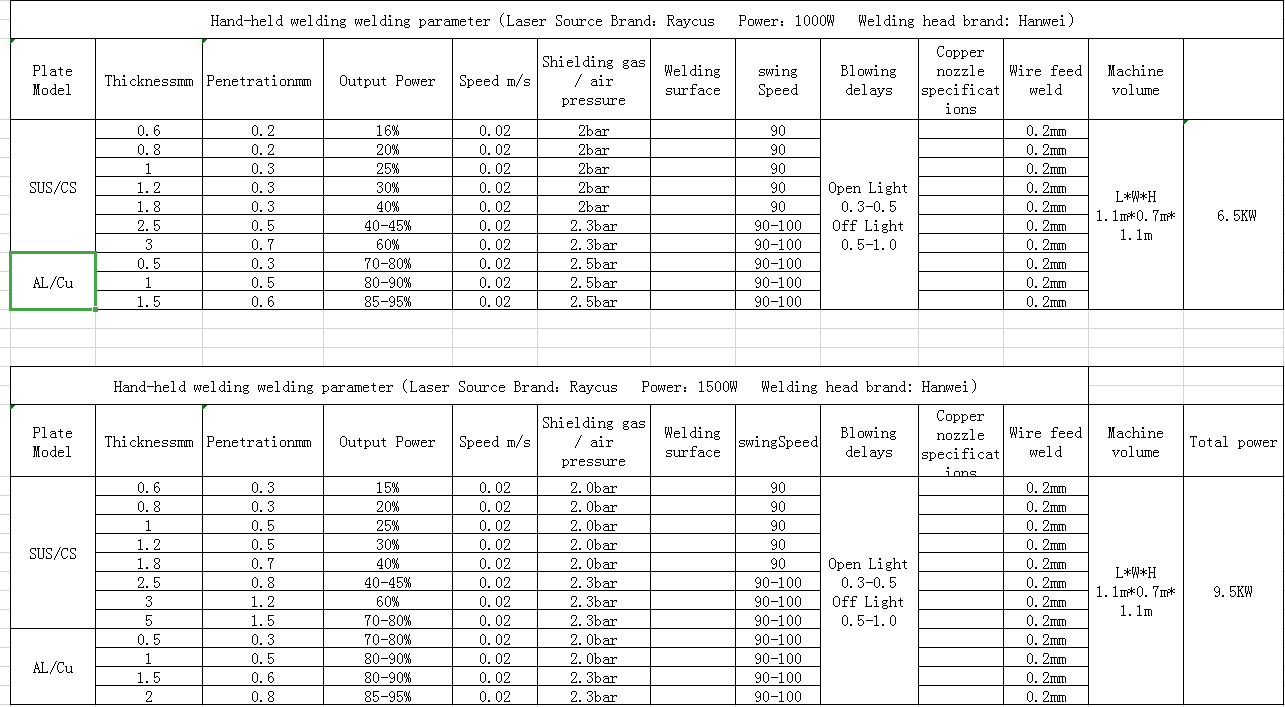

Welding parameter kumatshini welding laser

Uqwalaselo

| Amandla eLaser | 1000w | 1500W | 2000W | ||||||

| Welding Material | Yenziwe ngentsimbi eshayinayo | Intsimbi yeCarbon | Aluminiyam | Yenziwe ngentsimbi eshayinayo | Intsimbi yeCarbon | Aluminiyam | Yenziwe ngentsimbi eshayinayo | Intsimbi yeCarbon | Aluminiyam |

| Ukutyeba kweWelding (Mm) | 2 | 2 | 1 | 3 | 3 | 2 | 4 | 4 | 3 |

| Ukutyeba kweWelding (Intshi) |

|

|

|

|

|

|

|

|

|

| I-Welding Wire eguquguqukayo | I-Welding Wire Diameter 0.8-1.6mm | ||||||||

| Imfuneko ye-Weld Seam | IFiller Wire Welding≤1Mm Swinging Welding ≤15% yoButyebi bePlates≤0.3Mm | ||||||||

| Ubunzima bomatshini | 220Kg | 220Kg | 300Kg | ||||||

| Ubungakanani bomatshini(Mm) | 954X715X1080 | 954X715X1080 | 1155X715X1160 | ||||||

| Welding Gun Line Ubude | 10m (Ityhubhu yokuFindisa ngocingo yesiXhobo socingo sineemitha ezi-3 ubude) | ||||||||

| Welding Gun Weight | Uhlobo lwesipili esingcangcazelisayo(Qi Lin):0.9Kg | ||||||||

| Amandla omatshini | 7kw | 9kw | 12kw | ||||||

| Ulwimi luyaxhaswa | Umgangatho: isiTshayina, isiNgesi, isiKorea, isiVietnam, isiRashiya IsiJapan kunye neSpanish sinokwenziwa ngokwezifiso | ||||||||

| I-Voltage kunye neFrequency | UmGangatho:380V/50Hz Enye iVoltage kunye neFrequency ayikhethi | ||||||||

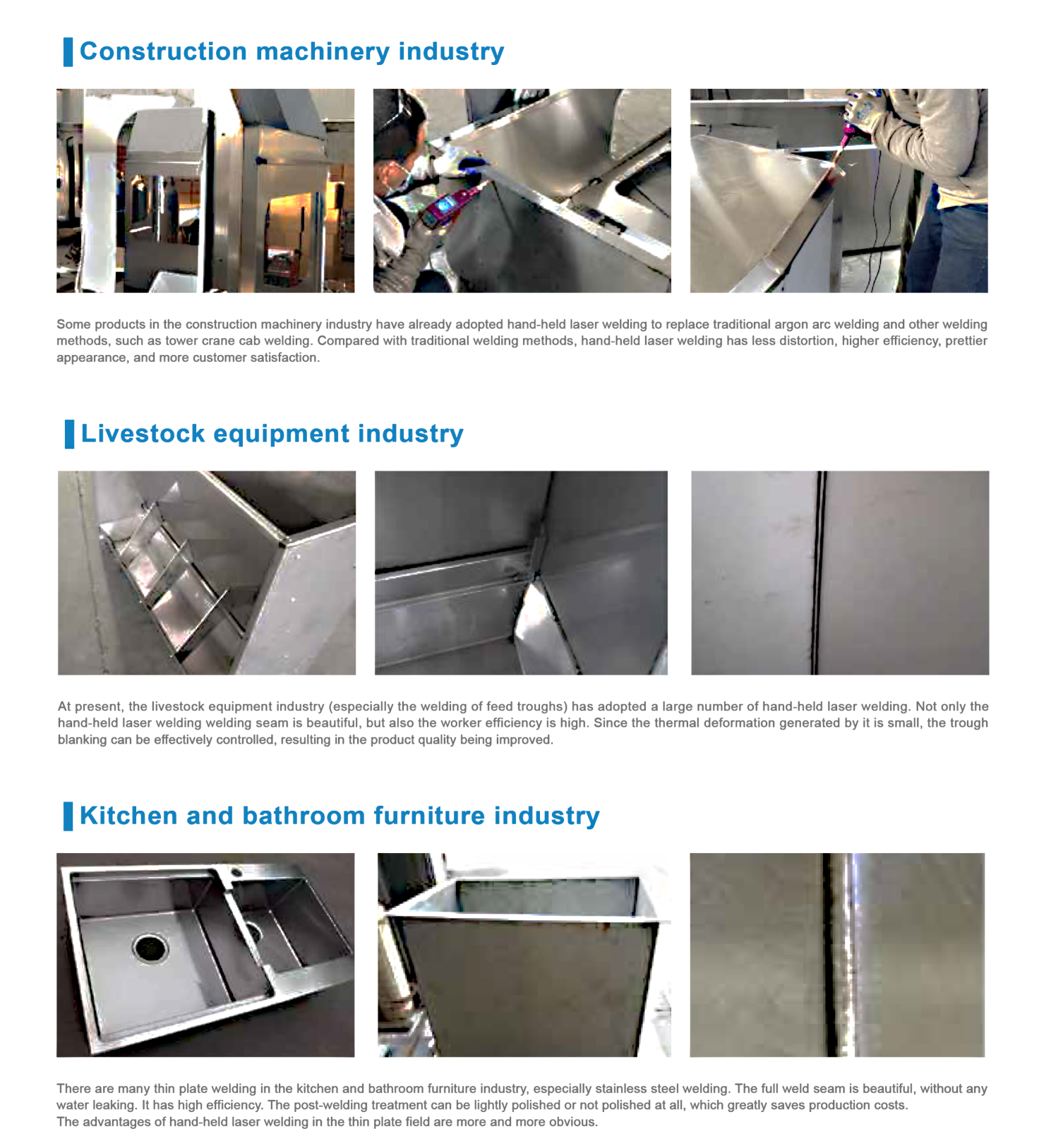

Ushishino lwezicelo

Oomatshini bokuwelda beLaser basetyenziswa kakhulu kushishino lokuhlambela: ukuwelda kwamalungu emibhobho yamanzi, amalunga okunciphisa, iiteyi, iivalve, kunye neeshawa. Umzi-mveliso weglasi: ukuwelda okuchanekileyo kwentsimbi engatyiwa, i-titanium alloy kunye nezinye izinto ezikwindawo ye-buckle, isakhelo sangaphandle kunye nezinye izikhundla zeeglasi. Umzi-mveliso we-Hardware: i-impeller, iketile, isiphatho, njl., ukuwelda kweendawo ezintsonkothileyo zokutywina kunye neendawo zokuphosa. Oomatshini bokuwelda beLaser basetyenziswa kakhulu kushishino lweemoto: iigaskets zesilinda se-injini, i-hydraulic tappet seal welding, i-spark plug welding, i-welding filter, njl.

Inzuzo yomatshini we-laser welding

1. Uluhlu olubanzi lwe-welding: Intloko ye-welding ebanjwe ngesandla ixhotywe nge-5m-10m ye-fiber optical yasekuqaleni, eyoyisa ukukhawulelana kwendawo yokusebenza kwaye ingasetyenziselwa i-welding yangaphandle kunye ne-long-distance welding;

2. Ukulungeleka kunye nokuguquguqukayo ekusebenziseni: I-laser welding ebanjwe ngesandla ixhotyiswe ngeepulleys ezihambayo, ezikhululekile ukubamba, kwaye zinokulungiswa nangaliphi na ixesha, ngaphandle kwesidingo sezikhululo ezisisigxina, ezikhululekile kunye neziguquguqukayo, kwaye zifanelekile kwiimeko ezahlukeneyo zokusebenza.

3. Iindlela ezahlukeneyo ze-welding: i-welding nakweyiphi na i-angle inokufezekiswa: i-welding ye-stitch, i-butt welding, i-vertical welding, i-flat fillet welding, i-internal fillet welding, i-welding yangaphandle ye-fillet, njl. I-Welding kuyo nayiphi na i-angle inokufezekiswa. Ukongeza, unokuphinda agqibe ukusika, i-welding kunye nokusika kunokutshintshwa ngokukhululekileyo, tshintsha nje umbhobho wobhedu we-welding kwi-nozzle yobhedu yokusika, efanelekileyo kakhulu.

4. Isiphumo esihle se-welding: i-laser ebambe ngesandla i-welding ye-fusion ishushu. Xa kuthelekiswa ne-welding yemveli, i-laser welding ine-energy ephezulu kwaye inokufikelela kwisiphumo esingcono se-welding. Ukulandelela iingxaki, ubunzulu obukhulu be-welding, ukunyibilika okwaneleyo, ukuqina kunye nokuthembeka, kunye namandla e-weld afikelela okanye agqithise isiseko sesinyithi ngokwaso, esingenakuqinisekiswa ngoomatshini abaqhelekileyo be-welding.

5. Umthungo we-Welding awufuni ukupholiswa: Emva kwe-welding yendabuko, indawo ye-welding kufuneka iphuculwe ukuze iqinisekise ukuguquguquka kwaye ingabi lukhuni. I-laser ye-laser ebanjwe ngesandla ibonisa nje iingenelo ezingaphezulu kwi-process effect: i-welding eqhubekayo, igudileyo ngaphandle kwezikali zeentlanzi, intle ngaphandle kwamanxeba, kunye neenkqubo zokugaya ezingaphantsi.

6. Akukho zixhobo ezisetyenziswayo kwi-welding: Kwiimpawu ezininzi zabantu, ukusebenza kwe-welding "izibuko kwisandla sasekhohlo kunye nocingo lwe-welding esandleni sokunene". Nangona kunjalo, ngomatshini we-laser welding welding, i-welding ingagqitywa ngokulula, kwaye iindleko zezinto eziphathekayo kwimveliso kunye nokucubungula ziyancipha.

7. Ngee-alamu ezininzi zokhuseleko, i-tip ye-welding isebenza kuphela xa itshintshi ichukumisa xa ichukumisa isinyithi, kwaye ukukhanya kuvaliwe ngokuzenzekelayo emva kokuba i-workpiece isusiwe, kwaye umtshini wokuthintela unomshini wokushisa womzimba. Ukhuseleko oluphezulu, ukuqinisekisa ukhuseleko lwabaqhubi ngexesha lomsebenzi.

8. Gcina iindleko zabasebenzi: Xa kuthelekiswa ne-arc welding, iindleko zokucubungula zingancitshiswa malunga ne-30%. Umsebenzi ulula kwaye kulula ukuwufunda kwaye ukhawuleza ukufunda, kwaye umda wezobugcisa womqhubi awuphezulu. Abasebenzi abaqhelekileyo banokuqeshwa emva koqeqesho olufutshane, kwaye banokufikelela ngokulula kwiziphumo eziphezulu ze-welding.