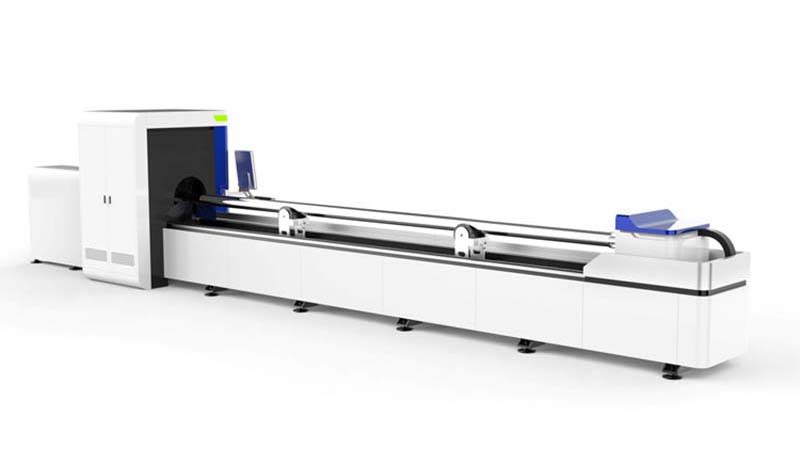

Ngophuhliso olukhawulezayo lwetekhnoloji yelaser,oomatshini bokusika umbhobho we-laserzisetyenziswa kakhulu nangakumbi kumashishini amaninzi. Ukuvela kwezixhobo zokusika umbhobho we-laser kuzise utshintsho oluphazamisayo kwinkqubo yokusika kwishishini lemibhobho yentsimbi yemveli. Umatshini wokusika umbhobho we-laser uneempawu ze-automation ephezulu, ukusebenza kakuhle, kunye nokukhutshwa okuphezulu. Kwimibhobho yezinto ezahlukeneyo, akukho mfuneko yokutshintsha ii-saw blades ezihambelanayo, kwaye akukho mfuneko yokuyeka phakathi. Ifanelekile kakhulu kwimveliso yobuninzi.

Ukuze kugcinwe ukusebenza okuphezulu komatshini wokusika umbhobho we-laser, kuyimfuneko ukugcina izixhobo rhoqo, ngoko njani ukugcina umatshini wokusika umbhobho? Ukongeza kulondolozo lwebhedi yezixhobo, ukugcinwa kwe-chuck nako kubaluleke kakhulu. Ezi zilandelayo ziingcebiso ezi-4 zokugcina i-chuck.

1. Ukuthambisa i-chuck, sebenzisa i-lubricant kwi-chuck rhoqo ukuze uqinisekise ukuba i-chuck isenokuba nokuchaneka okuphezulu ngexesha lokunyakaza. Nika ingqalelo xa uthambisa. Ukuthambisa okungafanelekanga kunokubangela ukuba i-pneumatic chuck ingakwazi ukusebenza ngokwesiqhelo xa uxinzelelo lomoya lusezantsi, amandla okubamba abuthathaka, ukuchaneka kokubambezeleka akuchanekanga, ukunxiba akuqhelekanga okanye kubambekile, ke nikela ingqalelo kumsebenzi ochanekileyo wokuthambisa xa uthambisa.

1. Ukuthambisa i-chuck, sebenzisa i-lubricant kwi-chuck rhoqo ukuze uqinisekise ukuba i-chuck isenokuba nokuchaneka okuphezulu ngexesha lokunyakaza. Nika ingqalelo xa uthambisa. Ukuthambisa okungafanelekanga kunokubangela ukuba i-pneumatic chuck ingakwazi ukusebenza ngokwesiqhelo xa uxinzelelo lomoya lusezantsi, amandla okubamba abuthathaka, ukuchaneka kokubambezeleka akuchanekanga, ukunxiba akuqhelekanga okanye kubambekile, ke nikela ingqalelo kumsebenzi ochanekileyo wokuthambisa xa uthambisa.

2. Sebenzisa igrisi ye-molybdenum disulfide, edla ngokuba mnyama, kwaye ugalele igrisi kwi-chuck nozzle de igrisi igqithe kumhlathi okanye umngxuma ongaphakathi wechuck. Ukuba i-chuck isebenza ngesantya esiphezulu ixesha elide okanye isebenzisa i-oxygen-assisted processing ixesha elide, i-lubrication eninzi iyadingeka, kwaye i-frequency ye-lubrication kufuneka ilungiswe ngokweemeko zokusebenza zangempela.

3. Emva kokuba ukucubungula kugqitywe rhoqo emva kwexesha elithile, kuyimfuneko ukusebenzisa umpu womoya ophezulu wokunyamezela ukujongana nothuli olusele kwi-chuck ngokwayo kunye ne-slideway. Kunconywa ukuba uhlambulule imihlathi ye-chuck rhoqo emva kweenyanga ezi-3-6 ukugcina indawo ecocekileyo kunye ne-lubricate. Khangela ukuba amalungu onakele kwaye agugile, kwaye uwabuyisele ukuba ngaba ukunxitywa kunzulu. Emva kokuhlolwa, imihlathi kufuneka ithanjiswe ngokufanelekileyo kwaye ifakwe ngaphambi kokusetyenziswa.

4. Izixhobo zokusebenza ezikhethekileyo okanye ii-workpieces ezingekho mgangathweni kufuneka zibotshwe kwaye zilungiswe ngee-chucks ezithile. Umbhobho we-laser oqhelekileyo wokusika i-chuck ifanelekile kwiimilo zetyhubhu ezilinganayo kunye ezivaliweyo. Ukuba uyisebenzisa ngenkani ukucinezela izixhobo zokusebenza ezingaqhelekanga okanye ezingaqhelekanga, iya kubangela ukungahambi kakuhle kwe-chuck; ukuba uxinzelelo lonikezelo lomoya lwe-chuck luphezulu kakhulu, i-chuck iya kuba phantsi koxinzelelo oluphezulu okanye emva kokuvala I-chuck iphinda ibambe i-workpiece, eya kunciphisa ubomi be-chuck kwaye ibangele iingxaki ezifana nokukhutshwa ngokugqithiseleyo kwe-chuck.

5. Thintela isinyithi esiveziweyo se-chuck ekubeni siruse. Ukuthintela umhlwa yenye ingongoma ephambili. Ukurusa kwe-chuck kuya kunciphisa amandla okubamba kwaye akunakuyibamba i-workpiece, echaphazela kakhulu ukuchaneka kwemveliso kunye nokusebenza kakuhle.

Le ndlela ingentla yindlela ephambili yokugcina umatshini wokusika umbhobho we-laser. Ngokuqinisekileyo, ukusetyenziswa ngokucokisekileyo komsebenzisi kunye namanyathelo okusebenza ngokusemgangathweni kwabasebenzi nazo ziyizinto ezibalulekileyo zokugcina ukusebenza komatshini wokusika umbhobho.

Ixesha lokuposa: Jan-19-2023