一.Intshayelelo yemveliso:

I-JCZ i-dual-axis enkulu-format splicing isebenzisa i-JCZ ibhodi yokulawula i-axis eyandisiweyo kabini ukuphumeza ukuphawula ukudibanisa ngaphaya kobubanzi besibuko sentsimi. Kucetyiswa ukuba kusetyenziswe ifomathi engaphezulu kwe-300 * 300, kuba ifomathi enkulu igqitywe ngezibuko zentsimi ezincinci zokuqhawula kunye nokumakisha, ngoko ke kukho inzuzo yokukhanya okuphezulu, ubunzulu bokuphawula okunzulu, njl.

二.Ufakelo lomatshini:

Ngenxa yokuba ezinye iindawo ziya kususwa ngexesha lenkqubo yokuhanjiswa, kufuneka uzifake ngokwakho emva kokufumana umatshini. Into oyifunayo ukuyifaka ibandakanya ikholomu kunye nendlela yokubona. Kwindlela yofakelo, bhekisa kumatshini wokumakisha oqhelekileyo.

三. Ukuqhuba uvavanyo:

Emva kokuba yonke i-hardware ifakwe, uvavanyo olulula lwe-single-run luyafuneka, kubandakanywa ukukhutshwa kokukhanya kunye neemvavanyo zokuhamba kwe-axis nganye.

1.Uvavanyo lokuqhuba:

Emva kofakelo, inyathelo lokuqala kukuhlanjululwa kwesiqhelo njengokuvavanya ukukhanya kunye nokulungiswa kokuphazamiseka.

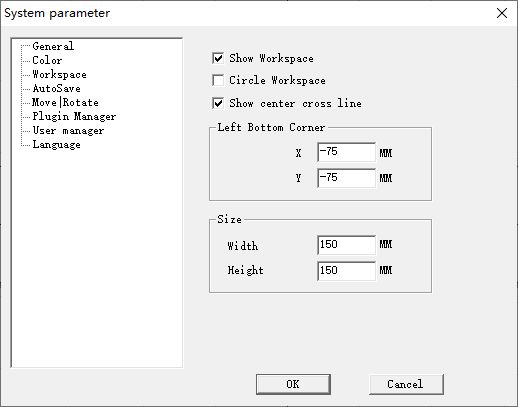

Gcwalisa indawo yendawo yeziko kunye nobukhulu ngokobukhulu be-lens yentsimi. Cofa kwiiparameters ezantsi kojongano oluqhelekileyo, kwaye ugcwalise ngokobungakanani boluhlu lwelensi yentsimi.

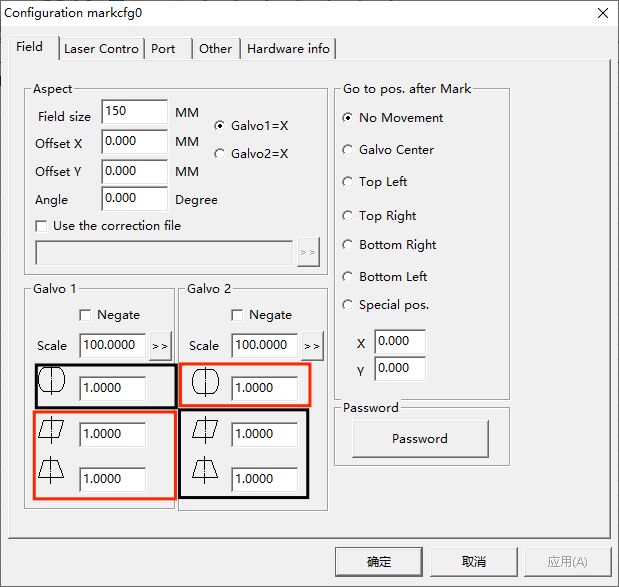

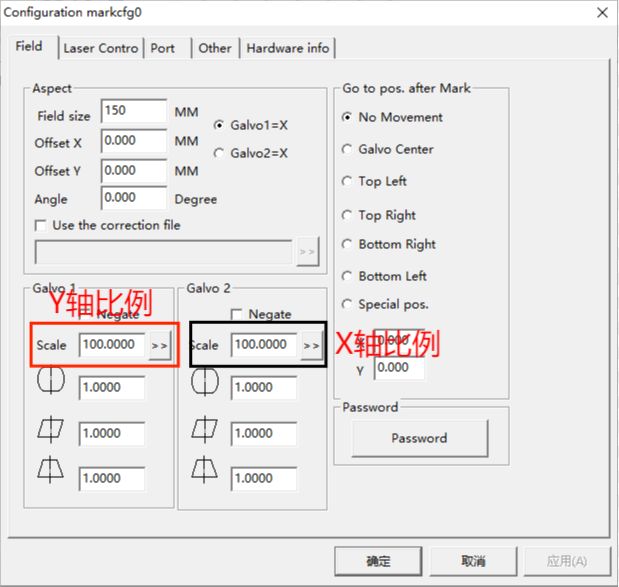

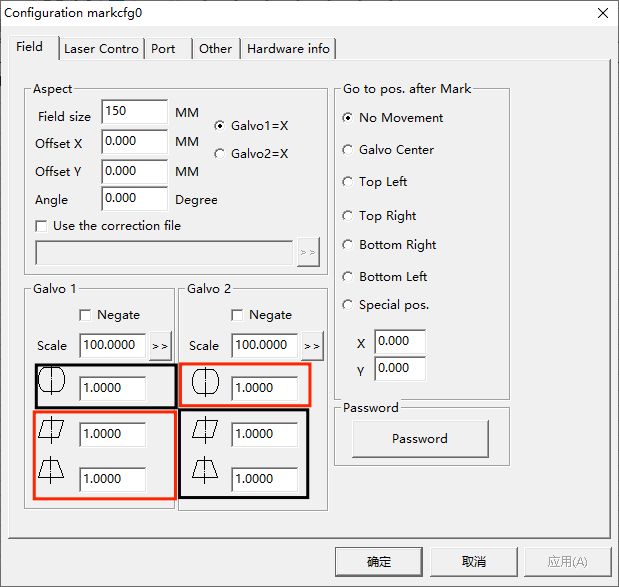

Ulungiso lwesikali, phawula eyona bhokisi inkulu ngokoluhlu lokumakisha, uze uyiphawule. Emva komlinganiselo, gcwalisa isikali esihambelanayo ngokwexabiso lomlinganiselo lokwenene. Ngokomzekelo, i-X axis yi-150mm, kwaye umlinganiselo wangempela yi-152mm. Gcwalisa lo mzobo ulandelayo, kunye ne-Y axis sisizathu esifanayo de ivume.

Emva koko gcwalisa iiparamitha zokulungisa ngokwemilinganiselo ye-square deformation elinganisiweyo, njengoko kuboniswe kumfanekiso, i-Y-axis deformation parameters ikwibhokisi ebomvu, kwaye i-X-axis deformation parameters ikwibhokisi elimnyama.

Isakhelo esiphawulweyo sisikwere, ngaphandle kokuguqulwa kwaye singenazo iincam zokucinga.

2. Lungisa ii-axis ezimbini:

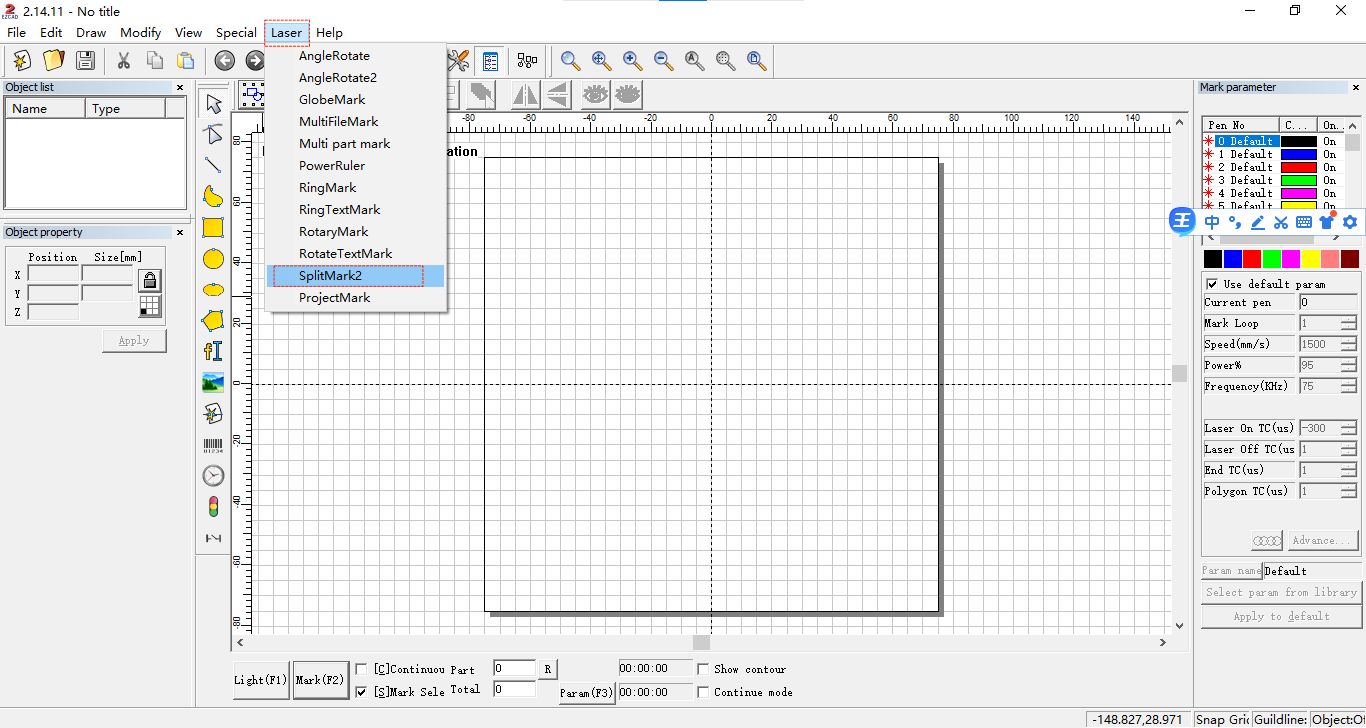

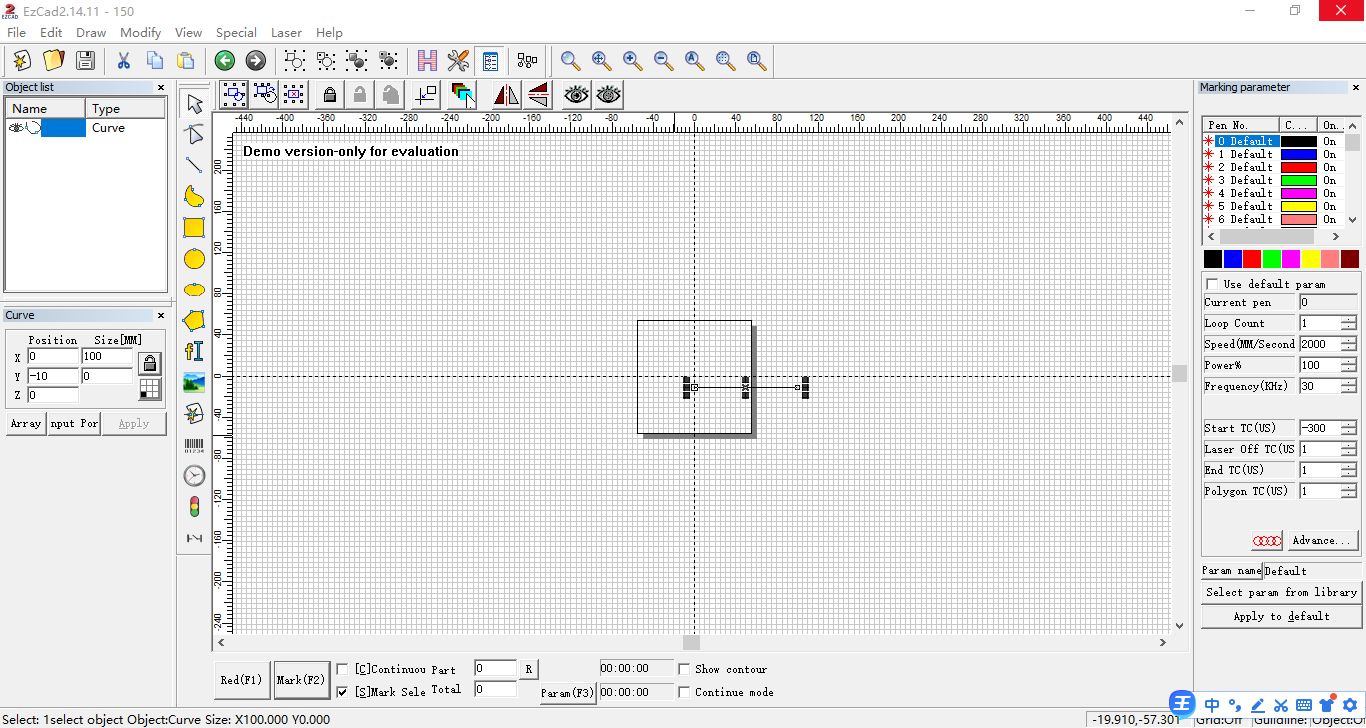

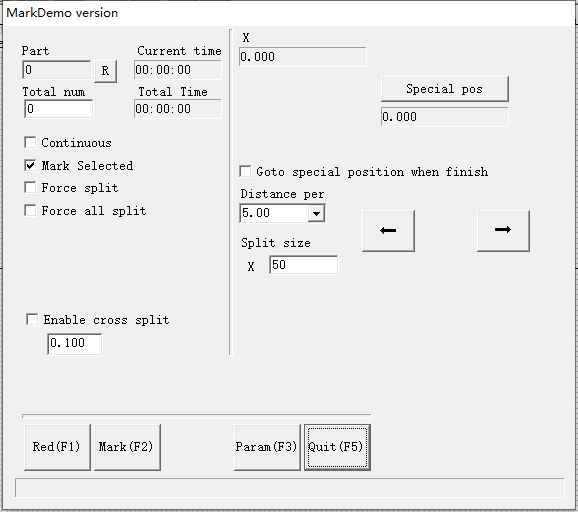

Phezulu kwesoftware, khetha iLaser -SplitMark2 ukufaka iSplitMark iphepha lomsebenzi.

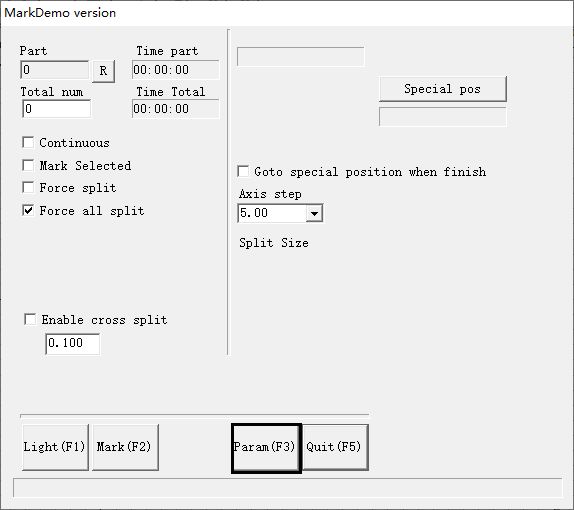

Eli liphepha lomsebenzi weSplitMark. Ngoku amazembe amabini angaphandle awakavulwa. Cofa "F3" ngezantsi ukufaka isethingi ye-axis yangaphandle.

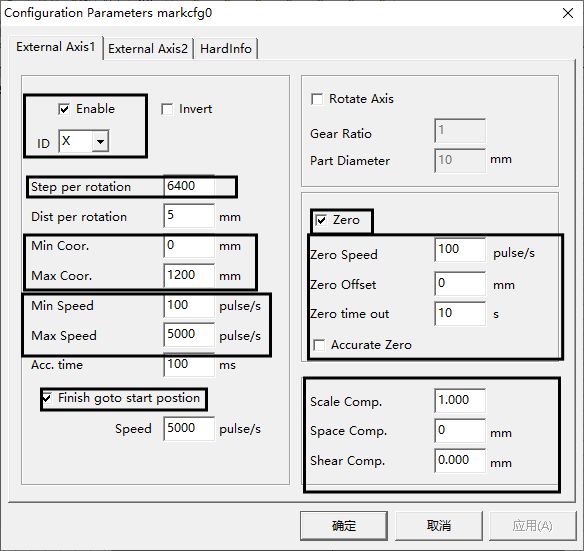

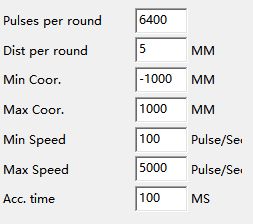

Thatha i-X isicwangciso sangaphandle njengomzekelo. Emva kokuvula, kufuneka ujonge iqhosha lokuvumela, khetha i-X njenge-ID, kwaye ugcwalise iiPulses kumjikelo ngamnye ongezantsi ukuze utshatise iseto yokwenyani yemoto, kungenjalo kuya kubakho iingxaki ezinje ngamanyathelo alahlekileyo okanye umgama ongonelanga wokuhamba. Ubuncinci be-Coor ngu-0, kwaye umgama ophezulu uzaliswe ngokuhambelana nobukhulu bokwenene bomatshini.

Isetingi engu-zero ineemeko ezintathu,Le yimbuyekezo enguziro phambili, emva kokuba inqaku elinguziro limiselwe, ulwalathiso lubuyela kwindawo enguziro phambili.,Le meko yimeko yembuyekezo enguziro. Emva kokumisela inqaku elingu-zero, i-motor ibuyela kwindawo engu-zero.,Kule meko, akukho nqaku zero, kwaye injini ayibuyeli ku-zero.

Emva kokumisela i-zero ye-return direction ye-axis nganye ukuba ichanekile, kuyimfuneko ukulinganisa ukuchaneka okukodwa kwe-axis nganye. Indlela yokulinganisa kukuzoba umgca othe tye oyi-100mm, 200mm, kunye ne-300mm, emva koko wenze uphawu lokucalula, ulinganise umgca wokumakisha emva kokumakisha, kwaye uthelekise iziphumo. , ngokwesikali sangempela, lungisa i-Dist kumjikelo ngamnye de uhlengahlengiso

ubude bethagethi buhambelana nobude obuphawulweyo.

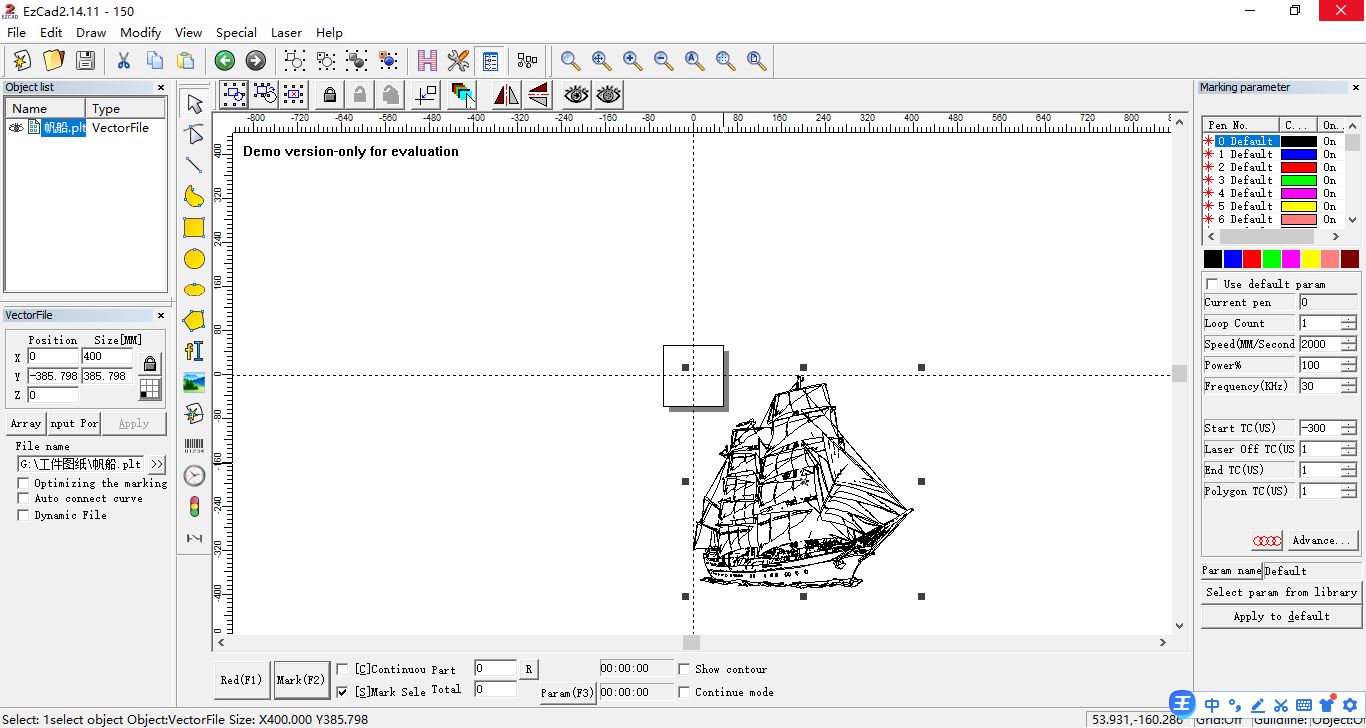

Emva kokuba umgama wesinyathelo ulungelelaniswa, umphumo wokuthunga kufuneka ulungelelaniswe. Usazoba umgca othe tye onobude obuyi-100mm, kwaye ubeke umgca kwikona esezantsi ekunene kulo lonke uluhlu olusebenzayo.

Emva koko ucofe i-SplitMark,Seta ubungakanani bokumakishwa kokwahlula, ukuseta ukuya kwi-30mm, qalisa ukumakisha, kwaye ujonge isiphumo.

Ukuba isiphumo sokuqhawula njengoko kubonisiwe kumfanekiso, oko kuthetha ukuba i-lens yentsimi ayihambelani ne-X-axis, kwaye i-angle ye-galvanometer okanye i-X-axis idinga ukulungiswa de i-interface ilula. Kukwanjalo kuhlengahlengiso lwe-Y-axis. Ukuba i-galvanometer ilungelelaniswe ukuba ihambelane ne-X-axis ngaphambili, kwaye ke le ngxaki yenzeke ngexesha lokulungiswa kwe-Y-axis, kufuneka ulungelelanise i-perpendicularity phakathi kwe-X-axis kunye ne-Y-axis de ulungelelaniso lugqityiwe.

3.Ukuqala kokumakisha:

Emva kokulungelelanisa umphumo we-splicing, ungaqala ukumakisha. Ukumakisha kufuneka kubekwe ipateni ukuba imakishwe kwikona esezantsi ekunene kuluhlu lokusebenza. Njengoko kubonisiwe kumzobo, kwaye uluhlu lwegrafu aludluli indawo ye-zero kunye noluhlu oluphezulu lwe-axis ye-XY.

Emva kokubeka umfanekiso, cofa i-SplitMark2, kwaye emva kokuseta ubungakanani bokwahlula, ungaqala ukumakisha.

Ukuba ingxaki yokuthunga yenzeke kwakhona ngexesha lenkqubo yokumakisha, nceda uphinde lo msebenzi ungentla.

Ixesha lokuposa: Feb-23-2023