Uhlobo lweRobhothi iLaser Welding Machine

Umboniso weMveliso

Ipharamitha yobugcisa

| IRobhothi yeAxis emithandathu | Tuling | Amacandelo Angundoqo | Umthombo weLaser |

| Ukusetyenziswa | Weld Metal | Max. Amandla emveliso | 2000W |

| Izinto Ezinokusetyenziswa | Isinyithi | Cnc Okanye Hayi | Ewe |

| Imo yokupholisa | Ukupholisa Amanzi | IiNkqubo zoMbane kunye nePeneumatic | Schneider |

| Ubude bamaza | 1090Nm | Amandla eLaser | 1000w/1500w/2000w |

| Ubunzima (Kg) | 600 Kg | Isiqinisekiso | Ce, Iso9001 |

| Amacandelo Angundoqo | IFayibha Laser Umthombo, iFayibha, Handle Laser Welding Head | Amanqaku okuThengisa aPhambili | Ukuchaneka okuphezulu |

| Umsebenzi | Metal Part Laser Welding | Ubude beFayibha | ≥10m |

| Amashishini asebenzayo | Iihotele, iiVenkile zeMpahla, iiVenkile zezinto zokwakha | Amacandelo Angundoqo | Umthombo weLaser |

| Indlela yokuSebenza | Nditsalekile | Emva kweNkonzo yeWaranti | Inkxaso ye-Intanethi |

| Ububanzi beNdawo ekuJoliswe kuyo | 50μm | UBonelelo oluphezulu | 1730mm |

| Uhlolo lwevidiyo oluphumayo | Kubonelelwe | IFomathi yoMzobo iyaxhaswa | Ai, Plt, Dxf, Dwg, Dxp |

| Indawo Yemvelaphi | IJinan, kwiPhondo laseShandong | Ixesha leWaranti | Iminyaka emi-3 |

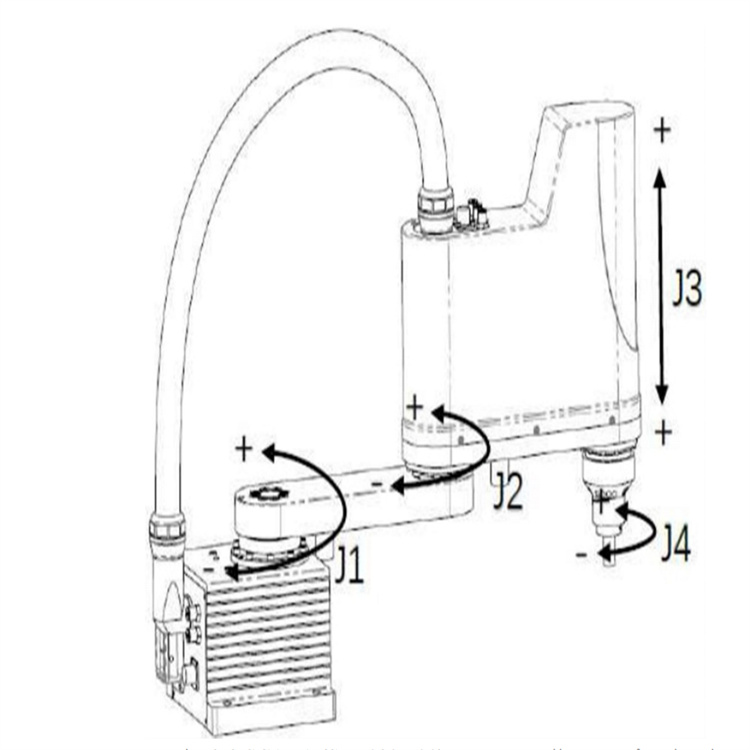

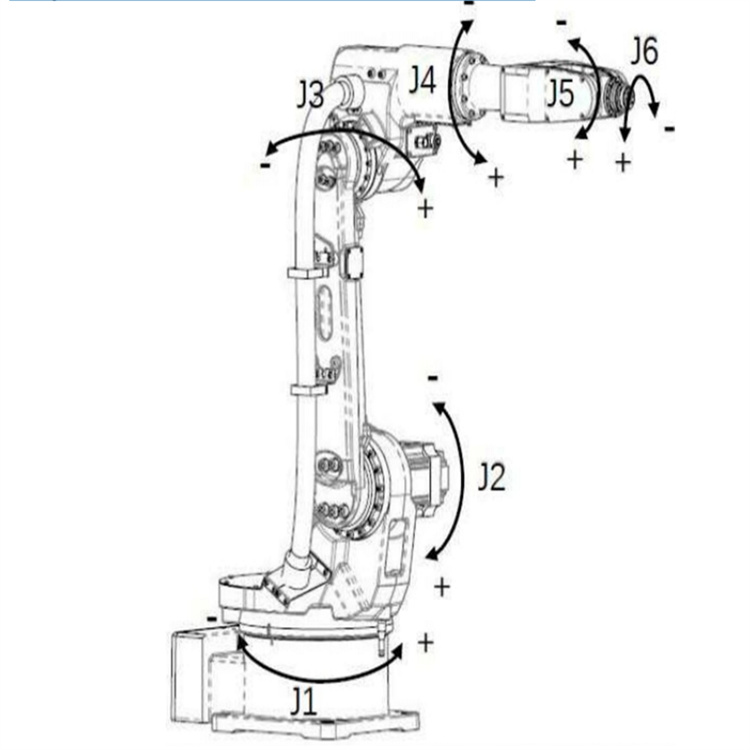

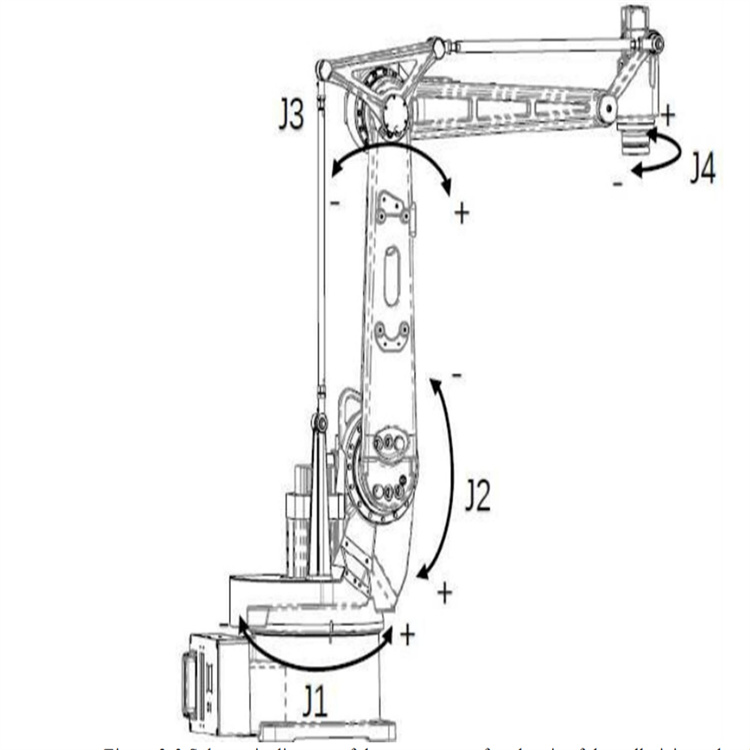

Ingalo yerobhothi

I-robot axis ingaba yi-axis ejikelezayo okanye i-axis yokuguqulela, kwaye imodi yokusebenza ye-axis inqunywe yisakhiwo somatshini. I-axis yerobhothi yahlulwe kwi-axis eshukumayo yomzimba werobhothi kunye ne-axis yangaphandle. I-shaft yangaphandle ihlulwe kwitafile ye-sliding kunye ne-positioner. Ngaphandle kokuba kuchazwe ngenye indlela, i-axis yerobhothi ibhekisa kwi-axis eshukumayo yomzimba werobhothi.

Iirobhothi zeTuring zahlulwe zaba ziindidi ezintathu zeerobhothi zamashishini:

Irobhothi ye-industrial six-axis: kubandakanywa ii-axes ezintandathu zokujikeleza

I-SCRA: iqulethe ii-axes ezintathu zokujikeleza kunye ne-axis enye yokuguqulela

I-palletizing manipulator: kubandakanywa i-shafts ezine ezijikelezayo Intshukumo edibeneyo yerobhothi iboniswe kumzobo.

Ukusetyenziswa komatshini wokuwelda weRobhothi

1.INdawo yokuVelisa oomatshini

Ngokuqiniswa kwemisebenzi ye-welding kushishino lokuvelisa oomatshini, ukusebenza kwe-welding kuneemeko zokusebenza ezimbi ngokwendalo kunye nemitha yokushisa enkulu, engumsebenzi oyingozi kakhulu. Kukwakho nezixhobo ezininzi ezinkulu kwimveliso yoomatshini, nto leyo enyusa ubunzima bokuwelda. , Irobhothi ye-Welding sisixhobo esizenzekelayo esisebenza kumsebenzi we-welding, ekhulula amandla omsebenzi wabasebenzi kwaye inceda ukuphucula inqanaba lokuzenzekelayo kwintsimi yokuvelisa oomatshini.

2.Imoto kunye nezixhobo zemoto:

Kwiminyaka yakutshanje, ukuze kuhlangatyezwane neemfuno zoluntu, ishishini leemoto libonise uphuhliso olwahlukeneyo. I-welding yesiko ayinakuhlangabezana neemfuno eziphezulu ze-welding zemoto kunye ne-auto part parts. , I-welding seam intle kwaye iqinile. Kwiindibano zocweyo zale mihla zokuvelisa iimoto, iintambo zokudityaniswa kweerobhothi zewelding zenziwe.

3.Izixhobo zombane:

Intsimi yezixhobo zombane ineemfuno eziphezulu zomgangatho wokuwelda. Ngokunyuka kwemfuno yezixhobo ze-elektroniki eluntwini, izixhobo ze-elektroniki zikwajongene nemingeni enzima ngelixa zikhula ngokukhawuleza. Iirobhothi zokuwelda zinokuzinzisa umgangatho we-welding ngelixa uqinisekisa ukusebenza kakuhle kwemveliso. I-welding echanekileyo yezixhobo iphindwe kathathu ukuya kane ngaphezu kweyomsebenzi wezandla.

4. I-Aerospace:

Kulwakhiwo lwenqwelomoya, kukho malunga ne-1,000 lamalungu e-welding yomzimba, kwaye phantse amalungu angama-10,000 abandakanyekayo. Uninzi lwamacandelo abalulekileyo okuthwala umthwalo wenqwelomoya asebenzisa amacandelo adityanisiweyo. Umzimba wenqwelomoya uphantsi koxinzelelo olukhulu ngexesha lokubhabha, ngoko ke i-welding Iimfuno zingqongqo, kwaye irobhothi ye-welding inokuguquguquka ukuseta iiparitha ze-welding ngokusebenzisa itekhnoloji yokulandelela umthungo we-welding ukuwelda ngokuchanekileyo ubume benqwelomoya.

Ukugcinwa komatshini

- Indlela yokutya ngocingo. Kubandakanywa nokuba ngaba umgama wokuxheshisela ngocingo uqhelekile, nokuba umjelo wokuxheshisela ngocingo wonakele, nokuba kukho isivusi esingaqhelekanga; Ingaba ukuhamba kwegesi kuqhelekileyo; Ingaba inkqubo yokukhusela itotshi ye-welding iyinto eqhelekileyo. (Akuvumelekanga ukuvala itotshi yokuwelda kumsebenzi wokhuseleko lokhuseleko) ;Ingaba inkqubo yokujikeleza kwamanzi isebenza ngokuqhelekileyo;Vavanya i-TCP (kuyacetyiswa ukuba uqulunqe inkqubo yovavanyo kwaye uyiqhube emva kweshifti nganye)

2. Ukuhlolwa nokugcinwa kweeveki ngeeveki

1. Khuhla iaxis nganye yerobhothi; Jonga ukuchaneka kwe-TCP; Jonga inqanaba leoli elishiyekileyo. ;Khangela ukuba indawo enguziro ye-axis nganye yerobhothi ichanekile; Coca isihluzo emva kwetanki yamanzi yomatshini wokuwelda. Coca isihluzo kwindawo yokungenisa umoya ecinezelweyo; Coca ukungcola kumlomo wetotshi yetotshi ukunqanda ukuvaleka kwamanzi; Coca indlela yokutyisa ucingo, kubandakanywa ivili lokutya, ivili lokucofa ucingo kunye netyhubhu yesikhokelo socingo; Jonga ukuba umbhobho wombhobho kunye nombhobho wocingo olukhokelayo zonakele okanye zophukile. (Kucetyiswa ukuba ususe yonke i-hose bundle kwaye uyihlambulule ngomoya ocinezelweyo); Khangela ukuba inkqubo yokukhusela i-torch ye-welding iyinto eqhelekileyo kwaye ingaba iqhosha langaphandle lokumisa likaxakeka liqhelekileyo.