Abathathu kumatshini wokuwelda weLaser omnye

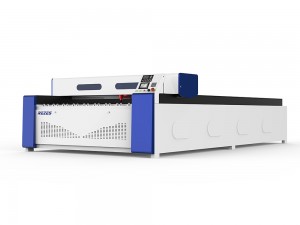

Umboniso weMveliso

Ipharamitha yobugcisa

| Isicelo | I-Laser Welding Cutting kunye nokuCoca | Izinto Ezinokusetyenziswa | Izinto zentsimbi |

| Laser Source Brand | Raycus/MAX/BWT | CNC okanye hayi | Ewe |

| Pulse Ububanzi | 50-30000Hz | Ububanzi beNdawo ekuJoliswe kuyo | 50μm |

| Amandla emveliso | 1500W/2000W/3000W | Isoftware yokulawula | URuida/Qilin |

| Ubude beFayibha | ≥10m | Ubude bamaza | 1080 ±3nm |

| Isiqinisekiso | CE, ISO9001 | Inkqubo yokupholisa | Ukupholisa amanzi |

| Indlela yokuSebenza | Ngokuqhubekayo | Uphawu | Ukugcinwa okuphantsi |

| Ingxelo yoVavanyo koomatshini | Kubonelelwe | Uhlolo lwevidiyo oluphumayo | Kubonelelwe |

| Indawo yeMvelaphi | IJinan, kwiPhondo laseShandong | Ixesha lewaranti | Iminyaka emi-3 |

Ividiyo yomatshini

Iimpawu eziNtathu kumatshini wokuwelda weLaser enye

1. Ubuninzi bamandla aphezulu kunye namandla aphezulu e-welding

Ubuninzi be-laser beam beam yomatshini wokuwelda we-fiber laser uphezulu kakhulu, onokunyibilika ngokukhawuleza izinto zetsimbi kwaye wenze i-weld eqinileyo. Amandla e-welding anokulingana okanye aphezulu kunaleyo yempahla yomzali.

2. Iiwelds ezintle, akukho post-processing efunekayo

Iintsimbi eziveliswa nge-laser welding zihamba kakuhle kwaye zifanayo, ngaphandle kokusila okongeziweyo okanye ukupolisha, okunciphisa kakhulu iindleko ze-post-processing. Kufanelekile ngokukodwa kumashishini aneemfuno eziphezulu zokubonakala kwe-welding, njengemveliso yensimbi engenasici, imboni yokuhlobisa isinyithi, njl.

3. Ukukhawuleza kwe-welding kunye nokuphucula ukusebenza kakuhle kwemveliso

Xa kuthelekiswa neendlela zemveli ze-welding (ezifana ne-TIG / MIG welding), isantya somatshini we-fiber laser welding eqhubekayo inokunyuswa ngamaxesha angama-2-10, iphucula kakhulu ukusebenza kakuhle kwemveliso, kwaye ifanelekile kwiimeko zemveliso yobuninzi.

4. Indawo encinci echaphazelekayo ukushisa kunye ne-deformation encinci

Ngenxa yeempawu ezigxininisiweyo ze-laser, igalelo lokushisa kwindawo ye-welding lincinci, linciphisa ukuguqulwa kwe-thermal ye-workpiece, ngokukodwa ifanelekileyo kwiindawo ezichanekileyo ze-welding, njengamacandelo e-elektroniki, izixhobo zonyango, njl.

5. Unako ukuwelda izinto ezahlukeneyo zetsimbi, ezinoluhlu olubanzi lwezicelo

Isebenza kwinsimbi engenasici, i-carbon steel, i-aluminium alloy, ubhedu, i-nickel alloy, i-titanium alloy kunye nezinye izinyithi kunye ne-alloys yazo, esetyenziswa ngokubanzi kwimveliso yemoto, i-sheet metal processing, i-aerospace, izixhobo zombane, izixhobo zonyango kunye namanye amashishini.

6. Iqondo eliphezulu lokuzenzekelayo, linokuhlanganiswa kunye ne-robot welding

Umatshini we-fiber we-laser welding oqhubekayo unokudibaniswa kunye neerobhothi kunye neenkqubo ze-CNC ukuphumeza i-welding automated, ukuphucula inqanaba lokuvelisa ngokukrelekrele, ukunciphisa ukungenelela kwezandla, kunye nokuphucula ukuhambelana kwemveliso kunye nokuzinza.

7. Ukusebenza okulula kunye neendleko eziphantsi zokugcinwa

Isixhobo samkela i-interface ye-industrial touch interface, iiparamitha ezihlengahlengiswayo, kunye nokusebenza okulula; i-fiber laser inobomi obude (ngokuqhelekileyo ukuya kuthi ga kwiiyure ze-100,000) kunye neendleko eziphantsi zokugcinwa, ezinciphisa kakhulu iindleko zokusetyenziswa kumashishini.

8. Inkxaso ephathwayo kunye neendlela ezizenzekelayo

Unokukhetha intloko ye-welding ye-handheld ukuphumeza i-welding eguquguqukayo, efanelekileyo kwi-workpieces enkulu okanye engaqhelekanga; inokusetyenziswa kunye ne-automated workbench okanye irobhothi ukuhlangabezana neemfuno zemveliso yomgca wokuhlanganisa.

9. Ubuhlobo bendalo kunye nokhuseleko, akukho slag ye-welding, akukho msi kunye nothuli

Xa kuthelekiswa nokuwelda kwemveli, ukuwelda ngelaser akuvelisi umsi omninzi, iintlantsi, kunye ne-welding slag, ehambelana nokusingqongileyo kwaye ikhuselekile, kwaye ihlangabezana nemigangatho yanamhlanje yemveliso eluhlaza.

Iisampulu zokuwelda

Inkonzo

1.Iinkonzo ezenzelwe wena:

Sinikezela ngoomatshini be-fiber laser welding elungiselelweyo, eyenzelwe kwaye yenziwe ngokweemfuno zabathengi. Ingaba ngumxholo we-welding, uhlobo lwempahla okanye isantya sokulungisa, sinokuyilungisa kwaye siyenze ngokweemfuno ezithile zomthengi.

2.Ukubonisana kwangaphambili kunye nenkxaso yobugcisa:

Sineqela elinamava leenjineli ezinokubonelela abathengi ngeengcebiso zokuthengisa kwangaphambili kunye nenkxaso yobugcisa. Ingaba kukukhethwa kwezixhobo, iingcebiso zesicelo okanye isikhokelo sobugcisa, sinokunika uncedo olukhawulezayo nolusebenzayo.

3.Ukuphendula ngokukhawuleza emva kokuthengisa

Ukubonelela ngenkxaso yobugcisa ngokukhawuleza emva kokuthengisa ukusombulula iingxaki ezahlukeneyo abahlangabezana nazo abathengi ngexesha lokusetyenziswa.

FAQ

Q: Zeziphi izinto ezinokudityaniswa ngumatshini we-laser welding?

A: Umatshini we-fiber we-laser welding oqhubekayo ufanelekile kwizinto ezahlukeneyo zetsimbi, ezifana: insimbi engenasici, i-carbon steel, i-aluminium alloy, ubhedu, i-nickel alloy, i-titanium alloy, i-galvanized sheet, njl.

Kwiintsimbi ezibonisa kakhulu (ezifana nobhedu, i-aluminium), kuyimfuneko ukukhetha amandla afanelekileyo e-laser kunye neeparitha ze-welding ukufumana iziphumo ezilungileyo ze-welding.

Q: Yintoni ubukhulu be-welding ye-laser welding?

A: Ubukhulu be-welding buxhomekeke kumandla we-laser.

Umbuzo: Ngaba i-laser welding ifuna igesi yokukhusela?

A: Ewe, irhasi yokukhusela (i-argon, initrogen okanye igesi exubeneyo) iyafuneka, kwaye imisebenzi yayo ibandakanya:

- Thintela i-oxidation ngexesha le-welding kwaye uphucule umgangatho we-weld

- Nciphisa isizukulwana se-weld porosity kwaye uphucule amandla e-welding

- Ukukhuthaza ukuqiniswa kwechibi elinyibilikisiweyo kwaye wenze i-weld ibe lula

Q: Uthini umahluko phakathi komatshini wokuwelda we-laser ophathwayo kunye nomatshini wokuwelda we-laser?

A: I-Handheld: Ilungele ukusebenza okuguquguqukayo, inokuwelda iimilo ezingaqhelekanga kunye nezixhobo zokusebenza ezinkulu, ezifanelekileyo kwimveliso yebhetshi encinci naphakathi.

I-Automation: Ifanelekile kwimveliso enkulu, esemgangathweni, inokudibanisa iingalo zerobhothi kunye neendawo zokusebenza ze-welding ukuphucula ukusebenza kakuhle kwemveliso.

Umbuzo: Ngaba i-deformation iya kwenzeka ngexesha le-laser welding?

A: Xa kuthelekiswa neendlela zemveli ze-welding, i-laser welding inegalelo eliphantsi lobushushu kunye nendawo encinci echaphazelekayo ukushisa, kwaye ngokuqhelekileyo ayivelisi ukuguqulwa okucacileyo. Kwizinto ezincinci, iiparameters zinokuhlengahlengiswa ukunciphisa igalelo lobushushu kunye nokunciphisa ngakumbi i-deformation.

Umbuzo: Bude kangakanani ubomi benkonzo yesixhobo?

A: Ubomi bethiyori ye-fiber laser bunokufikelela "kwiiyure ezingama-100,000", kodwa ubomi bokwenyani buxhomekeke kwindawo yokusetyenziswa kunye nokugcinwa. Ukugcina ukupholisa kakuhle kunye nokucoca rhoqo amacandelo optical kunokwandisa ubomi bezixhobo.

Umbuzo: Yeyiphi imiba ekufuneka ihlawulwe xa kuthengwa umatshini we-laser welding?

A: - Qinisekisa i-welding efunekayo kunye nobukhulu, kwaye ukhethe amandla afanelekileyo

- Qwalasela ukuba i-welding ezenzekelayo iyafuneka ukuze kuphuculwe ukusebenza kakuhle kwemveliso

- Khetha umenzi othembekileyo ukuqinisekisa umgangatho wezixhobo kunye nenkonzo emva kokuthengisa

- Qonda ukuba ngaba iinkqubo zokupholisa ezikhethekileyo okanye zokukhusela ziyafuneka