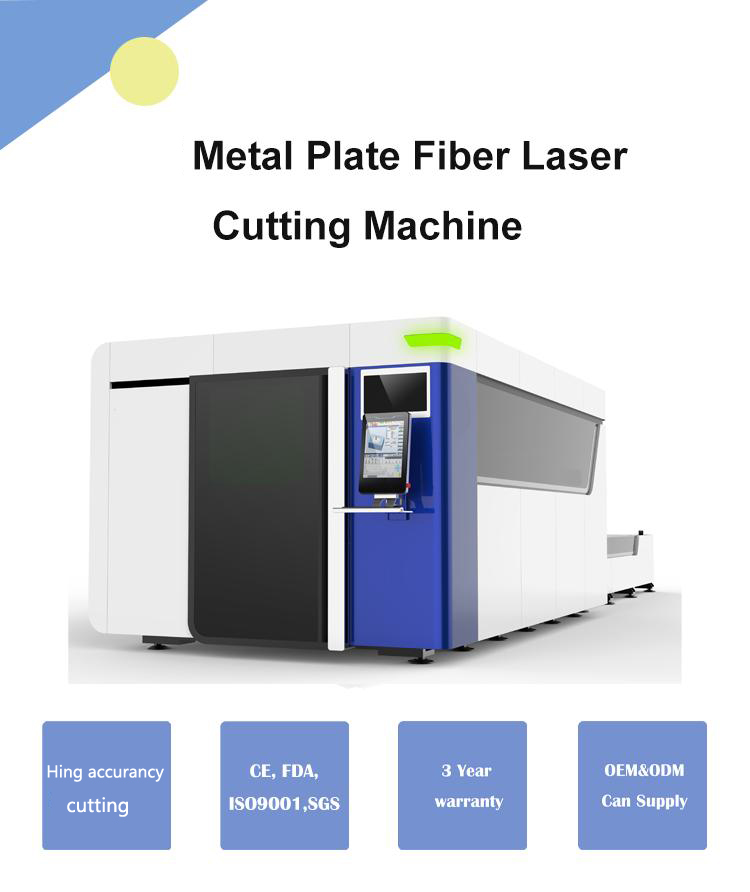

Umatshini wokusika weLaser we-Cover yonke

Umboniso weMveliso

Ipharamitha yobugcisa

| Isicelo | Ukusika iLaser | Izinto Ezinokusetyenziswa | Isinyithi |

| Indawo yokusika | 1500mm * 3000mm | Uhlobo lweLaser | IFayibha Laser |

| Isoftware yokulawula | Cypcut | Laser Head Brand | Raytools |

| I-Servo Motor Brand | Injini yaseYaskawa | Ingxelo yoVavanyo koomatshini | Kubonelelwe |

| IFomathi yoMzobo iyaxhaswa | I-AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC okanye hayi | Ewe |

| Amanqaku okuThengisa aPhambili | Ukuchaneka okuphezulu | Ubunzima | 4500kg |

| Indlela yokuSebenza | oluzenzekelayo | Ukubeka Ukuchaneka | ±0.05mm |

| ukuchaneka kokubeka kwakhona | ±0.03mm | Incopho yokuKhawuleza | 1.8G |

| Amashishini asebenzayo | Iihotele, iiVenkile zeMathiriyeli yoKwakha, Iplanti yokuVelisa | Iindawo zomoya | SMC |

| Indlela yokuSebenza | iliza eliqhubekayo | Uphawu | Ikhava epheleleyo |

| Ukusika isantya | kuxhomekeke kumandla kunye nobukhulu | Isoftware yokulawula | I-Tubepro |

| Ukusika Ukutyeba | 0-50mm | Guiderail Brand | HIWIN |

| Amalungu ombane | schneider | Ixesha lewaranti | Iminyaka emi-3 |

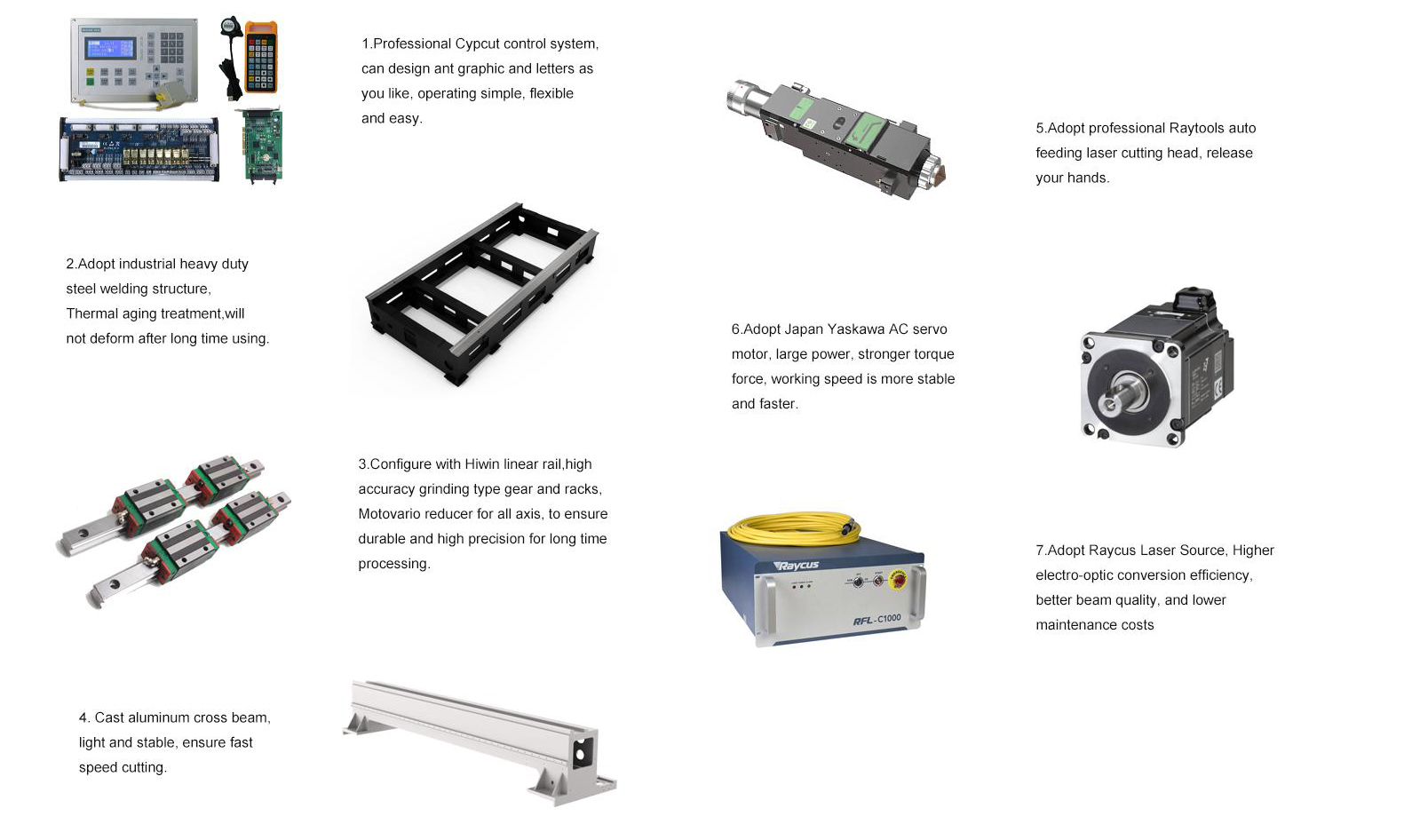

Amalungu omatshini

Ividiyo yomatshini

Umatshini wokusika weLaser we-Cover yonke

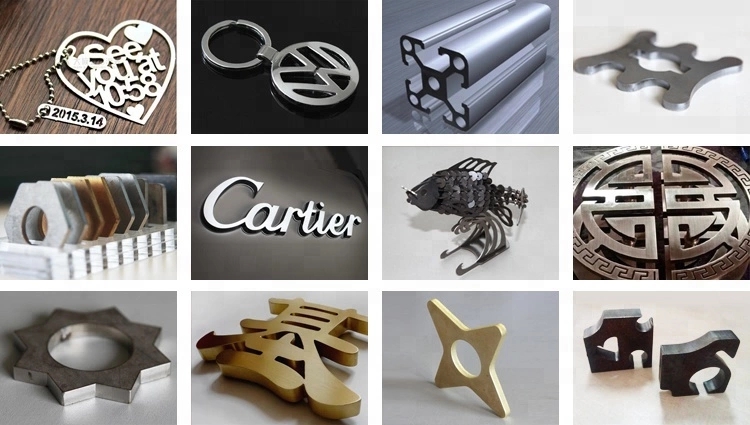

Ukusika iisampulu

Isicelo

1. Ushishino lweemoto

Oomatshini bokusika beLaser basetyenziswa kwiikhava zangaphambili zemoto, intsimbi yentsimbi, imibhobho yokukhupha imoto, njl. Ukuba umsebenzi owenziwe ngesandla usetyenziswa, kunzima ukufezekisa umgangatho ofunekayo wokusebenza kakuhle kunye nokuchaneka.

2. Ishishini lokuhombisa

Imboni yokuhlobisa idinga ukusebenzisa iigraphics ezininzi eziyinkimbinkimbi, kwaye umatshini wokusika i-laser unokuhlangabezana nokusetyenziswa kweli shishini kunye nesantya sokusika ngokukhawuleza kunye nokusika okuguquguqukayo, kwaye idume kakhulu phakathi kweenkampani zokuhlobisa. Emva kokuyila imizobo echaphazelekayo, ukungenisa ngokucofa okukodwa kunokunqunyulwa.

3.Ishishini lentengiso

Oomatshini bokusika iFayibha yeLaser basetyenziswa kakhulu ekwenzeni ibhilibhodi, iNtengiso, iMiqondiso, iMiqondiso, iileta zeMetal, iiLetter zeLED.

4.Izixhobo zendlu kunye noshishino lwasekhitshini

Izixhobo zasekhaya kunye nekhitshi zenziwe ngokusisiseko ngamacwecwe amancinci. Ngaphambi kwenkqubo yokunyathela kunye nokuzoba, umatshini wokusika i-fiber laser usetyenziselwa ukucubungula iisampuli ukuphuhlisa ngokukhawuleza iimveliso ezintsha. Isantya sokusika sezixhobo zokusebenza ze-laser sikhawuleza, esiphucula kakhulu ukusebenza kakuhle. Ngelo xesha, izixhobo zokucutshungulwa kwe-laser zinokuchaneka okuphezulu, okuphucula isivuno se-hoods kunye nezixhobo ezivuthayo. Kwezinye iimveliso ezinokwakheka okukhethekileyo, oomatshini bokusika i-fiber laser banenzuzo ekhethekileyo, kubandakanya iikhabhinethi zokuhambisa amandla, iikhabhinethi zokufayila, njl., zonke ezo ziyimveliso esemgangathweni yeeplate ezincinci kwaye zifuna ukusebenza kakuhle. Ukusetyenziswa koomatshini bokusika i-laser kunokuphucula kakhulu ukusebenza kakuhle.

5.Ishishini loomatshini bezolimo

Kukho iintlobo ezininzi ze sheet metal processing parts kwiimveliso zoomatshini bezolimo, kwaye zihlaziywa ngokukhawuleza. Amacandelo emveli ecwecwe lentsimbi yeemveliso zoomatshini bezolimo ngokuqhelekileyo zisebenzisa indlela yokugqobhoza, edla iimbumba ezininzi. Ukuba ukucutshungulwa kwamalungu kusahleli ngendlela yemveli, kuyakunqanda ngokunzulu ukutshintshwa kweemveliso. Iimpawu zokucubungula eziguquguqukayo ze-laser zibonakaliswa. Ukusetyenzwa kweLaser kunokuqonda ukusikwa kweemilo ezahlukeneyo zeepleyiti ngoncedo lwesoftware yokucwangcisa. Ukusebenzisa i-laser processing ayinayo isantya sokusebenza ngokukhawuleza, ukusebenza kakuhle okuphezulu, kunye neendleko eziphantsi, kodwa akufuneki ukuba kufakwe enye indawo yokubumba okanye izixhobo, ukunciphisa ixesha lokulungiselela imveliso. Inokuphinda ihambisane nesantya xa imveliso ihlaziywa, kwaye isitayela esitsha sinokunqunyulwa ngokuphinda kudweliswe kunye neprogram. Kulula ukuqaphela ukuqhubeka okuqhubekayo, ixesha lokutshintshwa kwe-laser beam lifutshane, kunye nokusebenza kakuhle kwemveliso kuphezulu. Ii-workpieces ezahlukeneyo zingafakelwa ngokuhlukileyo. Xa i-workpiece icutshungulwa, iindawo ezigqityiweyo zinokususwa kwaye i-workpiece eza kucutshungulwa inokufakwa ukuze iqonde ukusetyenzwa ngokuhambelanayo.

6.Ishishini loomatshini bokwakha

Kumashishini oomatshini bokwakha, i-fiber laser yokusika imingxuma ejikelezayo ingasetyenziswa nje ukuba ububanzi bomngxuma wokusebenza ojikelezayo bukhulu kunokuba okanye bulingana nobukhulu beplate, kunye nobukhulu kunye neemfuno zobubanzi zingaphakathi komthamo oqinisekisiweyo womatshini wokusika xa ujongene nobukhulu beplate ethile. I-laser inqumla ngokuthe ngqo izinto eziphathekayo, iphelisa inkqubo yokugaya kunye nokuphucula ukusebenza kakuhle kwemveliso yabasebenzi. Kwezinye iindawo zokusebenzela ezinemingxuma emininzi, umsebenzi wokubona umatshini wokusika we-fiber laser usetyenziselwa ukumisela indawo yomngxuma, ogcina ixesha lokubeka umngxuma kwinkqubo elandelayo yokugrumba, kwaye ikwagcina ixabiso lemveliso yetemplate yokugrumba, engaphuculi nje ukusebenza kakuhle kwemveliso, kodwa ikwaphucula ukuchaneka kwemveliso.